Galvanized Steel VS Aluminum – Which Material Is Best?

When choosing the right material for your project, you must consider many factors such as strength, durability, affordability, and more. Two materials that are often compared are galvanized steel and aluminum. While each has its own pros and cons, both are excellent choices for a variety of applications. In this article, we compare galvanized steel vs aluminum and help you make an informed decision.

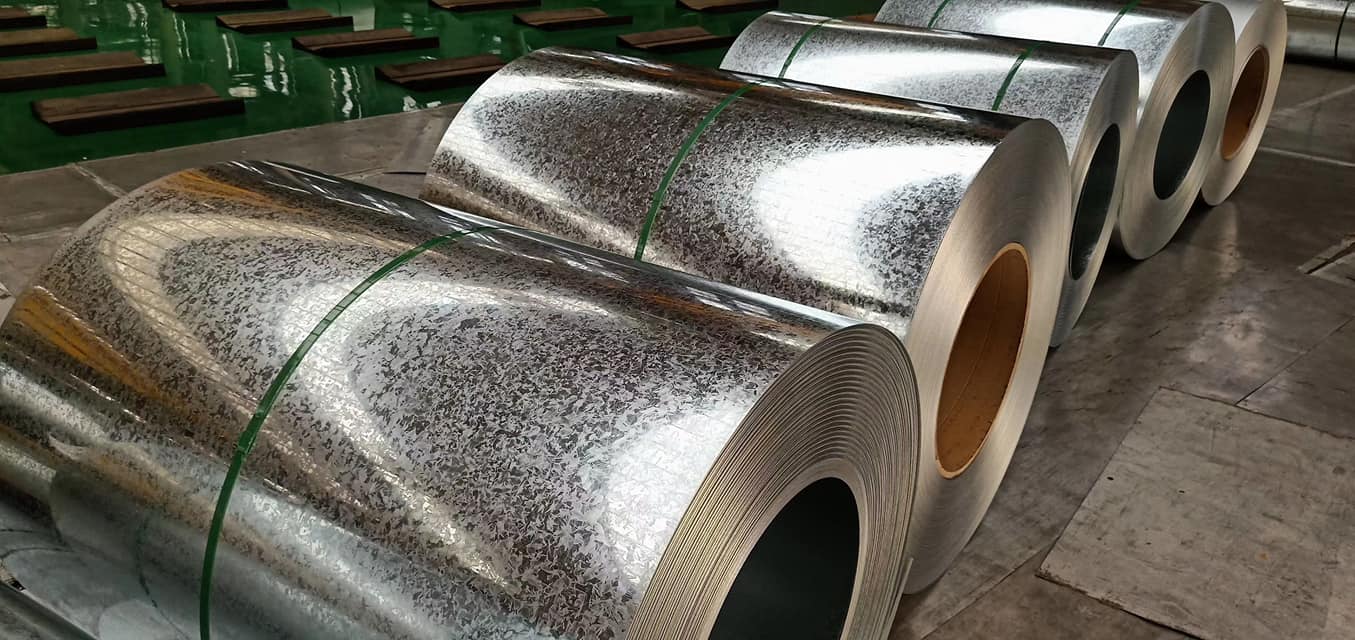

What is Galvanized Steel?

Galvanized steel is steel that has been coated with zinc to prevent rust and corrosion. The process is called galvanizing, and it involves dipping the steel into a bath of molten zinc. Zinc combines with steel to form a highly protective layer against rust and corrosion. Galvanized steel is known for its strength, durability and affordability, making it a popular choice in a variety of industries.

What is Aluminum?

Aluminum is a lightweight, versatile and corrosion-resistant metal. It’s the third most abundant element in the Earth’s crust, so it’s readily available and affordable. Aluminum is used in a wide range of applications, from aerospace and automotive to construction and packaging. It is known for its strength-to-weight ratio, which makes it an excellent choice for applications where weight is a concern.

Galvanized Steel VS Aluminum – Which Is Better?

strength:

Galvanized steel is stronger than aluminum, especially when it comes to impact resistance. It is also more resistant to bending and breaking, making it a better choice for applications where strength is critical, such as construction and transportation.

Durability:

Both materials are very durable, but galvanized steel is more resistant to rust and corrosion. Aluminum is more prone to corrosion and can corrode rapidly in certain conditions such as marine environments if not handled properly.

Affordability:

Galvanized steel is more affordable than aluminum, making it a popular choice in many industries. However, its affordability is often offset by the fact that it requires long-term maintenance to prevent rust and corrosion. Aluminum, on the other hand, is more expensive initially, but requires less maintenance and can have a longer life.

weight:

Aluminum is much lighter than galvanized steel, making it ideal for weight-conscious applications such as aerospace and automotive. Galvanized steel is much heavier and better suited for applications where weight is not a major concern, such as construction and infrastructure.

In summary:

When choosing between galvanized steel and aluminum, there are no clear answers. Each material has its own strengths and weaknesses, and the best choice will depend on your specific needs and requirements. Galvanized steel is strong, durable, and affordable, while aluminum is lightweight, corrosion-resistant, and requires less maintenance. It is important to carefully weigh the pros and cons of each material before making a decision.