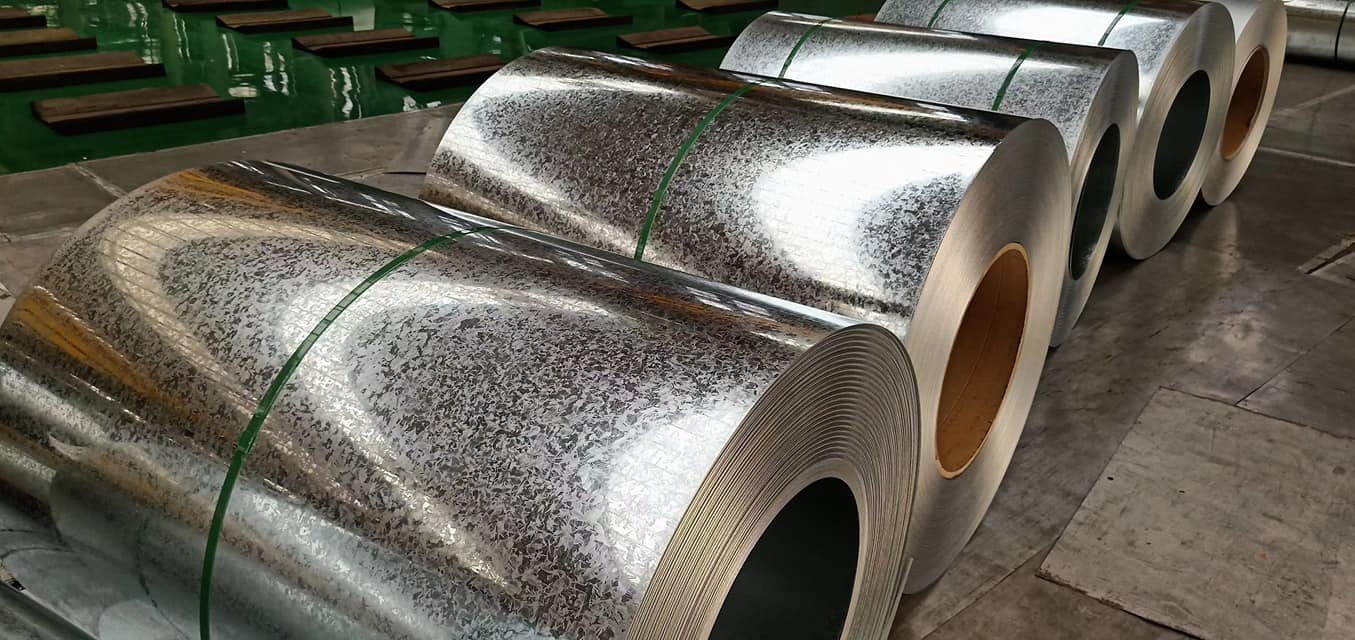

Highlights of Galvanized Steel Coil

Galvanized Steel Coil is a versatile and versatile construction material that offers numerous benefits to various industries. With superior corrosion resistance and durability, galvanized steel coils have become the first choice for construction projects, automotive manufacturing, agricultural applications and more. In this blog, we explore the salient features of galvanized steel coils that make them an indispensable material in modern architecture and beyond.

1. Excellent corrosion resistance

One of the key features that distinguishes galvanized steel coil from its peers is its unrivaled resistance to corrosion. Coils undergo a unique galvanizing process in which the steel surface is coated with a layer of zinc. This zinc coating acts as a protective barrier, preventing the steel substrate from coming into contact with moisture, oxygen and other corrosive elements. As a result, galvanized steel coils have an excellent service life, making them ideal for outdoor structures and any application exposed to harsh environmental conditions.

2. Durable

Galvanized steel coil offers exceptional durability, making it a reliable choice for a variety of applications. The galvanized layer not only protects the steel from rust, but also increases its strength. The coating acts as a sacrificial layer, and when scratched or slightly damaged, the coating sacrifices itself instead of the underlying steel. This self-healing property greatly extends the life of the galvanized steel coil and ensures its structural integrity even in harsh environments.

3. Wide range of applications

The adaptability of galvanized steel coils is another notable point of its popularity. The material is widely used in industries such as construction, automotive, agriculture and manufacturing. In construction, galvanized steel coils are commonly used for roofing, siding, gutters, and downspouts due to their durability and aesthetics. Its versatility also extends to the automotive industry, where it is used to produce body, chassis and other structural components.

4. Low maintenance requirement

One of the most notable advantages of galvanized steel coils is their low maintenance requirements. Once installed, the zinc coating on the steel surface provides long-term protection with minimal maintenance. Galvanized steel coils reduce the need for frequent inspections and repairs compared to other materials. This capability not only saves time and resources, but also contributes to overall cost-effectiveness.

5. Sustainable and environmentally friendly

Galvanized steel coils are considered a sustainable and environmentally friendly material choice. The galvanizing process consumes minimal energy, making it an efficient and environmentally friendly solution. In addition, the recyclability of galvanized steel is a significant advantage. At the end of its useful life, galvanized steel can be easily recycled and reused, reducing waste and conserving natural resources.

To sum up, the highlights of galvanized steel coils are undeniable. Its excellent corrosion resistance, long-lasting durability, wide range of applications, low maintenance requirements and sustainable features make it an excellent choice for many industries. As we continue to witness advancements in construction and fabrication, galvanized steel coil remains at the forefront, paving the way for stronger, longer-lasting structures and sustainable development.